Blog

When it comes to ensuring the safety and efficiency of electrical systems, a thermal imaging camera for electrical inspections is an invaluable tool. These devices leverage infrared technology to detect hidden issues like overheating components, loose connections, or overloaded circuits before they turn into costly failures or dangerous fires. Not only do they improve safety, but they also improve the accuracy and speed of inspections. Here’s a quick glimpse of why you might consider these cameras for your electrical needs:

- Non-contact and safe: Inspect electrical systems without direct contact.

- Fast and efficient: Quickly identify and classify potential problems.

- Preventive maintenance: Spot issues before they cause serious failures.

- Documentation-ready: Record findings for future reference and repair planning.

As Mike Martinez, owner of Accountable Home Services specializing in restoration and home improvement, I bring years of experience in using thermal imaging cameras for electrical inspections. My team and I are committed to offering effective, reliable services to protect and improve your home. In the next section, you'll find more about how this technology can benefit your electrical inspections.

Understanding Thermal Imaging for Electrical Inspections

Thermal imaging cameras have revolutionized the way electricians conduct inspections. By leveraging infrared technology, these cameras detect thermal anomalies—areas where the temperature is higher or lower than expected. This capability is crucial for identifying overheating components and ensuring the safety of your electrical systems.

Thermal Anomalies and Overheating Detection

Electrical systems often give early warning signs of potential failures through heat. When a component like a transformer or circuit is malfunctioning, it generates excess heat. This is where a thermal imaging camera for electrical inspections shines. It captures these heat signatures and displays them as gradient colors, making it easy to spot issues like loose connections or overloaded circuits.

According to a report, loose connections and overloaded circuits are among the most common causes of electrical fires. By detecting these issues early, thermal imaging can prevent dangerous situations and costly repairs.

Safety First

One of the biggest advantages of using thermal imaging cameras is safety. Traditional inspection methods often require physical contact with electrical components, posing a risk of electric shock. Thermal cameras eliminate this risk by allowing inspectors to assess equipment from a safe distance. As Nick Gromicko, CMI®, points out, “No other technology allows electrical faults to be found as safely and as quickly as thermal imaging.”

Enhancing Inspection Efficiency

Thermal imaging is not only about safety; it's also about efficiency. These cameras can scan large areas quickly, identifying problem spots without interrupting power. This non-intrusive approach ensures that inspections are fast and do not disrupt normal operations.

For homeowners and property managers in the Denver area, this means less downtime and more peace of mind. With the ability to document findings, you can address issues before they escalate, potentially saving money on extensive repairs.

In the next section, we'll dive into the top thermal imaging cameras for electrical work, exploring their features and how they can improve your inspection process.

Top Thermal Imaging Cameras for Electrical Work

When it comes to electrical inspections, choosing the right thermal imaging camera can make all the difference. These cameras help identify potential electrical issues before they become serious problems. Let's take a closer look at some of the top options available, focusing on features like infrared resolution and image quality.

FLIR E6: A Reliable Choice

The FLIR E6 is a popular choice among professionals for its balance of performance and affordability. Known for its robust features, this camera offers an infrared resolution of 160 x 120, which is ideal for detecting thermal anomalies in electrical systems.

Why Choose FLIR E6?

- Image Quality: The FLIR E6 provides clear images that help pinpoint overheating components. Its MSX® image improvement adds visible light details to thermal images, making it easier to identify issues.

- Ease of Use: This camera is designed with user-friendly controls, allowing even those new to thermal imaging to operate it effectively. Its intuitive interface means you can focus on the inspection rather than the equipment.

- Durability: Built to withstand harsh environments, the FLIR E6 is rugged and reliable, making it perfect for tough job sites in Denver and beyond.

Infrared Resolution: Key to Accurate Detection

Infrared resolution is a critical factor when selecting a thermal imaging camera. It determines the level of detail you can see in thermal images. Higher resolution cameras capture more detail, making it easier to identify small but significant temperature differences.

Why Resolution Matters:

- Detailed Analysis: A higher resolution allows you to see finer details, which is essential for diagnosing complex electrical issues.

- Better Documentation: Clearer images provide better documentation of potential problems, which can be crucial for communicating issues to clients or team members.

Image Quality: Clarity Is Crucial

Image quality in thermal imaging cameras is not just about resolution but also how well the camera displays temperature differences. Cameras with superior image quality provide clearer and more accurate representations of the inspected area.

Benefits of High Image Quality:

- Precision: High-quality images enable precise identification of problem areas, reducing the risk of overlooking critical issues.

- Professional Reports: When documenting findings, clear images improve the professionalism and credibility of your reports.

In summary, choosing the right thermal imaging camera involves considering factors like infrared resolution and image quality. The FLIR E6 stands out as a reliable option that balances these features with durability and ease of use. For those in Denver looking to improve their electrical inspections, investing in a quality thermal imaging camera is a smart decision.

In the upcoming section, we’ll explore the benefits of using thermal imaging cameras, highlighting how they contribute to preventive maintenance and safety.

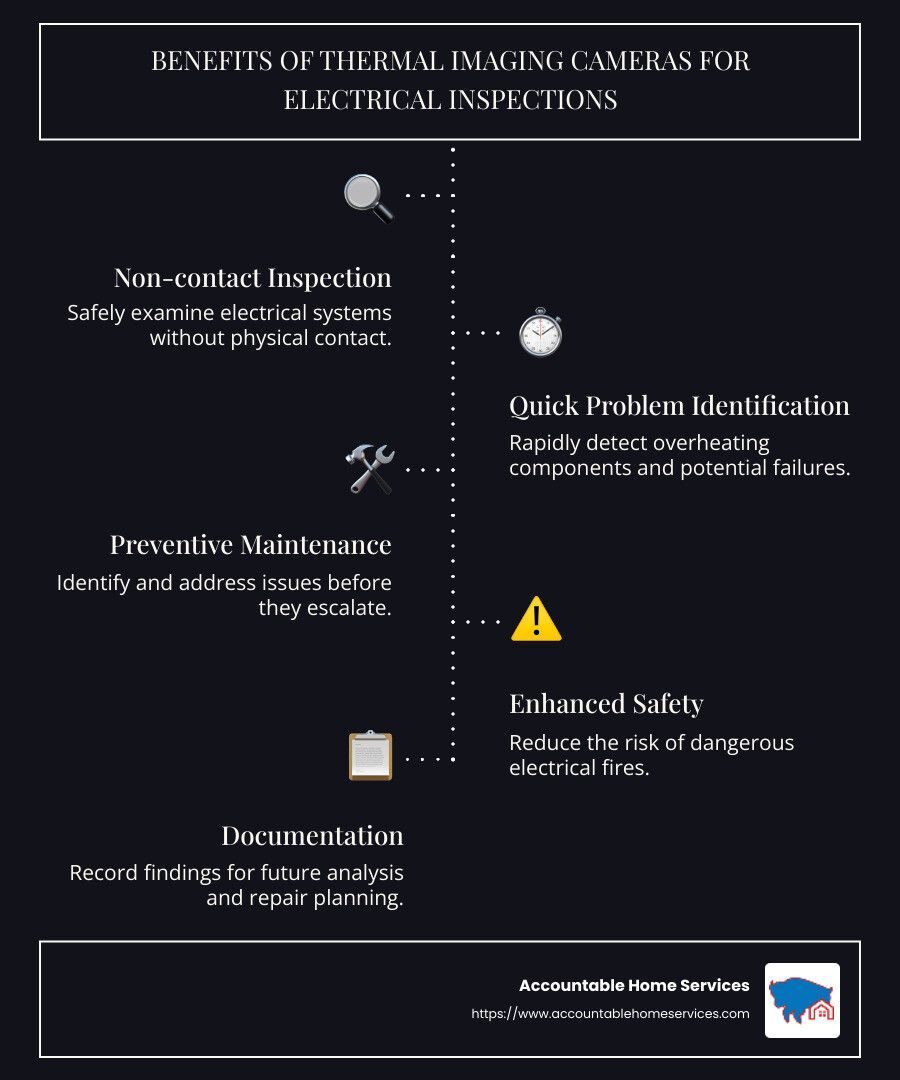

Benefits of Using Thermal Imaging Cameras

Thermal imaging cameras are a transformative tool for electrical inspections, offering numerous advantages that enhance safety and efficiency in maintaining electrical systems.

Non-Contact Inspection

A key feature of thermal imaging cameras is their ability to perform inspections without physical contact. This is particularly beneficial in electrical work.

- Safety First: By eliminating the need for direct contact, the risk of electrical shock or accidents is significantly reduced, which is crucial in high-voltage settings.

- Quick Assessments: These cameras allow for rapid scanning of large areas, facilitating the identification of potential issues without disrupting operations.

Preventive Maintenance

Thermal imaging cameras play a crucial role in preventive maintenance, helping to identify issues before they become major problems.

- Early Detection: By spotting hotspots and thermal anomalies early, you can address them before they result in equipment failure or electrical fires.

- Cost Savings: Early detection of problems can prevent costly repairs or downtime, making this a cost-effective approach in the long term.

Improved Safety

Using thermal imaging for inspections enhances safety for both inspectors and facilities.

- Identifying Hazards: These cameras can detect loose connections, overloaded circuits, and other hazards that are not visible to the naked eye.

- Documentation: Thermal images provide clear documentation of potential risks, which can be used to plan corrective actions and improve safety protocols.

In conclusion, thermal imaging cameras offer significant benefits for electrical inspections. They ensure safer, faster, and more thorough inspections, making them an essential tool for anyone involved in maintaining electrical systems. In the next section, we'll discuss how to choose the right thermal imaging camera, focusing on factors like resolution and durability.

How to Choose the Right Thermal Imaging Camera

Selecting the best thermal imaging camera for electrical inspections can feel overwhelming with so many options available. However, focusing on a few key factors can simplify your decision and ensure you get a camera that meets your needs.

Resolution

Resolution is crucial when choosing a thermal imaging camera. It determines the clarity and detail of the thermal images you capture.

- Higher Resolution for Detailed Images: Cameras with a higher infrared resolution, like 320 x 240 or even 640 x 480, provide clearer images. This makes it easier to spot small issues, like loose connections or minor overheating, that could cause big problems later.

- Consider Your Needs: If you're working in environments where precision is critical, opt for a higher resolution. For routine inspections, a mid-range resolution might suffice, balancing quality and cost.

Ease of Use

A camera that's easy to use makes inspections quicker and less stressful.

- User-Friendly Interface: Look for cameras with intuitive controls and clear displays. Features like LaserSharp™ AutoFocus can help you get precise images without fuss.

- Portability: A lightweight, compact design is ideal for carrying around during inspections. Some cameras even connect to smartphones, like the Thermal Master P2, offering a portable solution with powerful capabilities.

Durability

Durability is essential, especially if you're using the camera in harsh environments.

- Rugged Design: Choose a thermal camera that's built to withstand tough conditions. Look for features like weatherproofing and shock resistance.

- Longevity: Investing in a durable camera means you're less likely to face frequent repairs or replacements, saving money over time.

In summary, when choosing a thermal imaging camera, focus on resolution, ease of use, and durability. These factors ensure you get a tool that provides clear images, is straightforward to operate, and can withstand the demands of your work environment. Next, we'll answer some frequently asked questions about thermal imaging cameras for electrical inspections.

Frequently Asked Questions about Thermal Imaging Cameras for Electrical Inspections

Can thermal imaging detect electricity?

Thermal imaging cameras can't "see" electricity itself, but they can detect the heat that electrical components produce. When electrical systems have issues like overheating cables or faulty connections, they often generate excess heat. This heat shows up as bright spots on a thermal image, making it easier to spot problems before they lead to more serious issues, like electrical fires.

Do electricians use thermal imaging?

Absolutely! Electricians frequently use thermal imaging as a part of their routine maintenance checks. This technology helps them identify hot spots that might indicate potential problems. By catching these issues early, electricians can prevent equipment failures and ensure systems are running safely and efficiently. This proactive approach not only improves safety but also reduces downtime and repair costs.

Can thermal imaging see electrical wires?

While thermal imaging doesn't allow you to visually see hidden wires, it can reveal the heat patterns they produce. If wires are overheating, they will appear as warmer areas in a thermal image. This capability helps electricians identify potential fire hazards and other problems without needing to open walls or panels. It's a non-invasive way to ensure electrical systems are safe and functioning correctly.

By addressing these common questions, it's clear that thermal imaging cameras are invaluable tools for electricians. They provide a non-contact method to detect issues like overheating and faulty connections, ensuring electrical systems remain safe and efficient.

Conclusion

When it comes to ensuring the safety and efficiency of your home's electrical systems, Accountable Home Services stands out as a trusted partner. Our use of cutting-edge thermal imaging technology allows us to provide reliable solutions that help identify potential issues before they become serious problems.

Thermal imaging cameras are a game-changer for home safety. They enable us to conduct thorough inspections without the need for invasive procedures. By detecting heat patterns and anomalies, we can pinpoint areas of concern, such as overheating cables or faulty connections, which might otherwise go unnoticed. This proactive approach not only helps prevent electrical fires but also ensures your systems run smoothly and efficiently.

Our team of certified technicians is committed to delivering top-quality craftsmanship and transparent communication throughout the inspection process. We understand the unique needs of Denver homeowners and are dedicated to providing custom solutions that improve the safety and longevity of your home.

For a comprehensive thermal imaging inspection that prioritizes your home's safety and efficiency, trust Accountable Home Services. Contact us today for a free estimate and take the first step towards a safer, more reliable home.